Common processes for packaging printing.

一.Glossy PP Lamination

1. After printing, a transparent plastic film is applied to the surface of the printed material through hot pressing to protect and increase its luster. The surface is bright, as shown in the following figure.

2. The most basic process for surface treatment of paper boxes. Similarly, there is also gloss, but glue can enhance the hardness and tensile properties of paper.

二.Matt PP Lamination

1. After printing, a transparent plastic film is applied to the surface of the printed material through hot pressing to protect and increase gloss. The surface is matte, as shown in the following figure.

2. The most basic process for surface treatment of paper boxes is to apply gloss, but applying glue can enhance the hardness and tensile properties of the paper.

三.UV Coating

1.The prominent parts of the printed material need to be locally polished and brightened to make the local pattern more three-dimensional.

2. When printed with matte glue technology, there is no effect when printed with glossy glue.

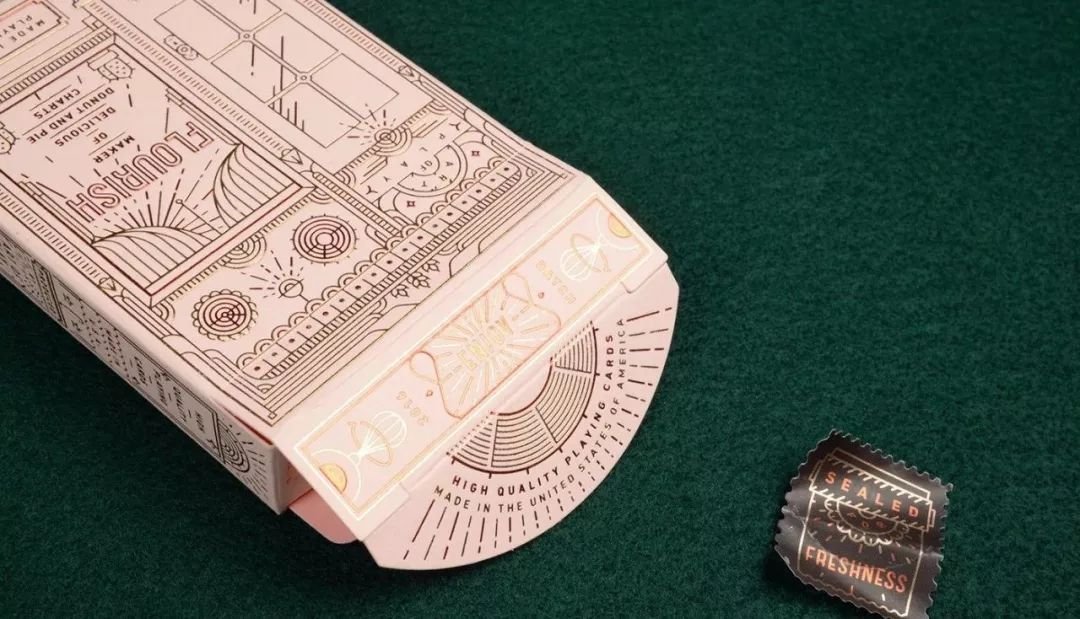

四.Foil Stamp

1. Hot stamping is the process of using the principle of heat pressure transfer to transfer the aluminum layer in the electroplated aluminum onto the surface of the substrate, creating a special metallic luster effect.

2. Printing materials include various colors such as gold, silver, red, green, blue, etc., but hot stamping can only be single color, with a wide variety of colors, but not all colors are available in the market.