Precautions when selecting self-adhesive label materials.

1.Do you know what a self-adhesive label is?

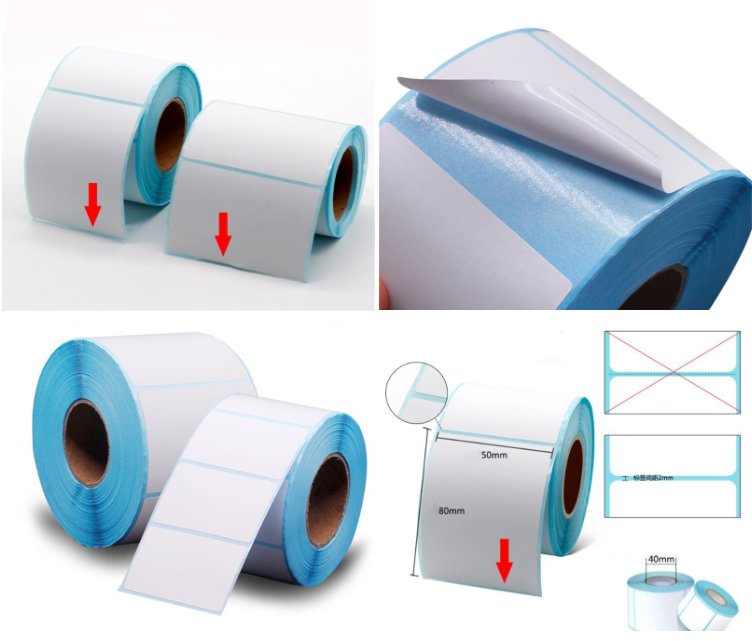

As the name suggests, the label comes with a non drying adhesive. Self adhesive refers to a type of material that uses paper, plastic, and other materials as the fabric, and the back of the fabric is coated with self adhesive. The base paper is a composite material of silicon protective paper, and after printing, die-cutting, and other processing, it becomes a self adhesive label.

Adhesive labels are ubiquitous in our daily lives and have a wide range of applications, including food, jewelry, clothing, beverages, and other products. It is also very convenient to use, and can be pasted at any time without affecting the beauty of the product. The self-adhesive label has the same characteristics as traditional labels: no need to brush or dip in water, high stickiness, etc. Self adhesive labels can also be covered with film and hot stamping processes, but these two processes are expensive and generally not used much, and are usually suitable for trademark logos, etc.

Self adhesive labels can be printed on the back, that is, printed with graphics and text on the adhesive surface, resulting in a double-sided label. If used on transparent products, the label content can be seen through the product and can also play a certain anti-counterfeiting role. Back printing is not suitable for large quantities and high precision labels. Self adhesive labels can also carry out information dissemination, have the function of promoting and marketing products, and can achieve the value of conveying the brand.

There are two types of self-adhesive labels. One type is non removable and permanent after sticking, and the other type is a detachable label. If customers want the product to achieve the expected results, they can choose the appropriate self-adhesive label according to their needs.

2.Issues to pay attention to when selecting self-adhesive label materials:

(1) For cylindrical bottles, especially those with a diameter less than 30MM, careful material selection is necessary.

(2) If the label size is too large or too small, attention should be paid to actual testing.

(3) If the object to be pasted has an irregular or even spherical surface, there are special considerations for the type of label material, thickness, and adhesive.

(4) Some rough surfaces, such as corrugated cardboard boxes, can affect labeling, and the varnish on the surface of corrugated cardboard boxes can also have an impact.

(5) Automatic labeling machine for labeling, and labeling tests can be conducted if necessary.

(6) Even if the label indicates room temperature, it is necessary to consider whether the export has experienced high temperatures during transportation and use.

(7) Excessive water or oil can affect the properties of the adhesive, so attention should be paid to the environment and temperature for labeling.

(8) Plasticizers sometimes seep out from the surface of soft PVC, so special attention should be paid to selecting appropriate adhesives.