Packaging quality knowledge sharing

Today, we mainly share knowledge about corrugated cardboard boxes used for transportation. The role of import and export packaging: safe transportation and storage; Convenient loading,

oday, we mainly share knowledge about corrugated cardboard boxes used for transportation. The role of import and export packaging: safe transportation and storage; Convenient loading, display and sales, etc; As a tool for product sales strategy, printing brand logos, sales advertisements, promotional messages, etc;

The conventional outer box transportation identification is the box mark, which includes the following contents:

Genuine mark

·Product name (product description) and brand logo;

·Order number (batch number);

·Model number (factory model or customer model), box number/total box number;

·Color and size;

·Made in China (* required);

·Pictorial markings for storage and transportation

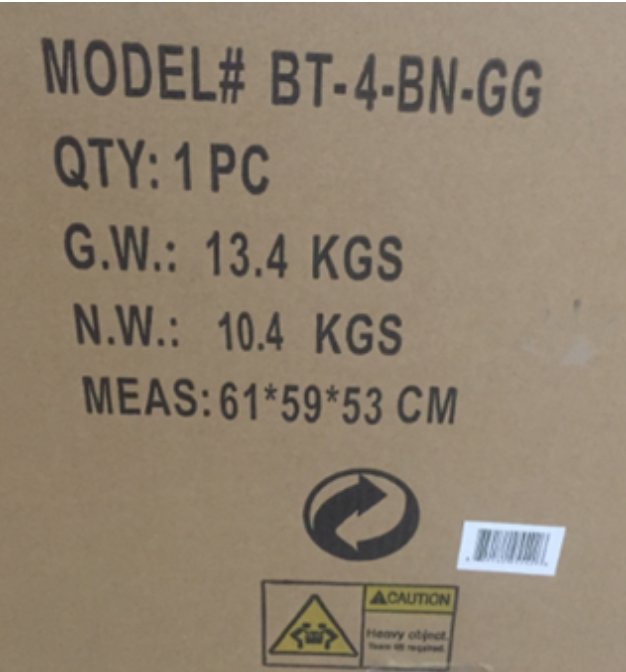

Side mark

·Model number (factory model or customer model);

·Number of boxes/box (xx PCS/CTN);

·Outer box size (centimeters/inches);

·Gross/Net Weight (W.: xx Kg/N.W.: xx Kg)

Quality inspection requirements for cardboard boxes

·Printing quality: Clear pattern and handwriting printing, consistent color, bright and bright;

·Sealing quality: There are no leaks around the box, and there are no gaps or seams after the closure of each box cover

There is a seam after sealing, which cannot be closed

·Dimensional tolerance: The tolerance between the inner diameter of the box and the design dimensions on the drawing should be maintained at ± 5mm, and for small boxes, it should be ± 3mm.

The overall dimensions should be basically the same to avoid the actual size being too small and unable to package the product normally;

·Folding times of the shaking cover (folded): After 180 degrees of opening and closing, it should be folded back and forth more than 5 times. In principle, there should be no cracks in the surface and inner layers;