Printing processing technology

The processing technology of printing graphic design refers to the re processing and production of printed products, mainly including surface finishing, forming processing,

book and magazine binding, and other processes. The commonly used processes include:

① Laminated. It can be divided into two types: covered sub film and covered bright film. The sub film is not as bright as the bright film, but more upscale.

Covering film can enhance the moisture resistance, sun protection, wear resistance, stain resistance, water resistance, heat resistance, and other properties of printed materials.

② Overglue. Press a layer of plastic film onto the printed material, including crystal film, light film, sub film, soft touch film, and other materials.

③ UV. It is a printing process that uses ultraviolet light to dry and solidify ink. It can increase the brightness and artistic effect of the product, protect the surface of the product,

have high hardness, resistance to corrosion and friction, and are not prone to scratches.

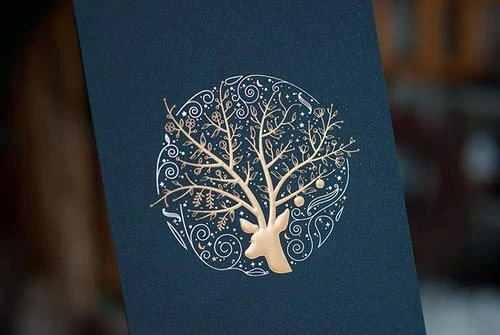

④ Hot stamping with gold and silver. Use heat transfer printing to heat stamp metal foil (gold, silver foil) onto the surface of the printed product, giving it a metallic texture and effect.

⑤ Bump imprinting. Use pressure to press graphics or text onto the surface of printed materials to achieve special tactile and visual effects.

In addition, the processing techniques for printed materials also include: flocking, embossing, polishing, mounting, binding, cutting, and other processing techniques.

Through these processes, it helps to improve the printing effect and grade of printed materials.