Detailed process for customizing packaging cartons

Detailed process for customizing packaging cartons

一、 Communication stage

① What type of packaging box do you need? What type of box is it for cosmetics, health products, or gifts? What material is used? What kind of effect is needed?

② What is the printing quantity? How long is the delivery cycle? What is the price?

③ Information and communication plan between both parties.

二、 Signing a contract

Confirm the style, material, size, design, production cycle, etc. of the product, and sign a cooperation agreement.

① Product Confirmation

1. Material

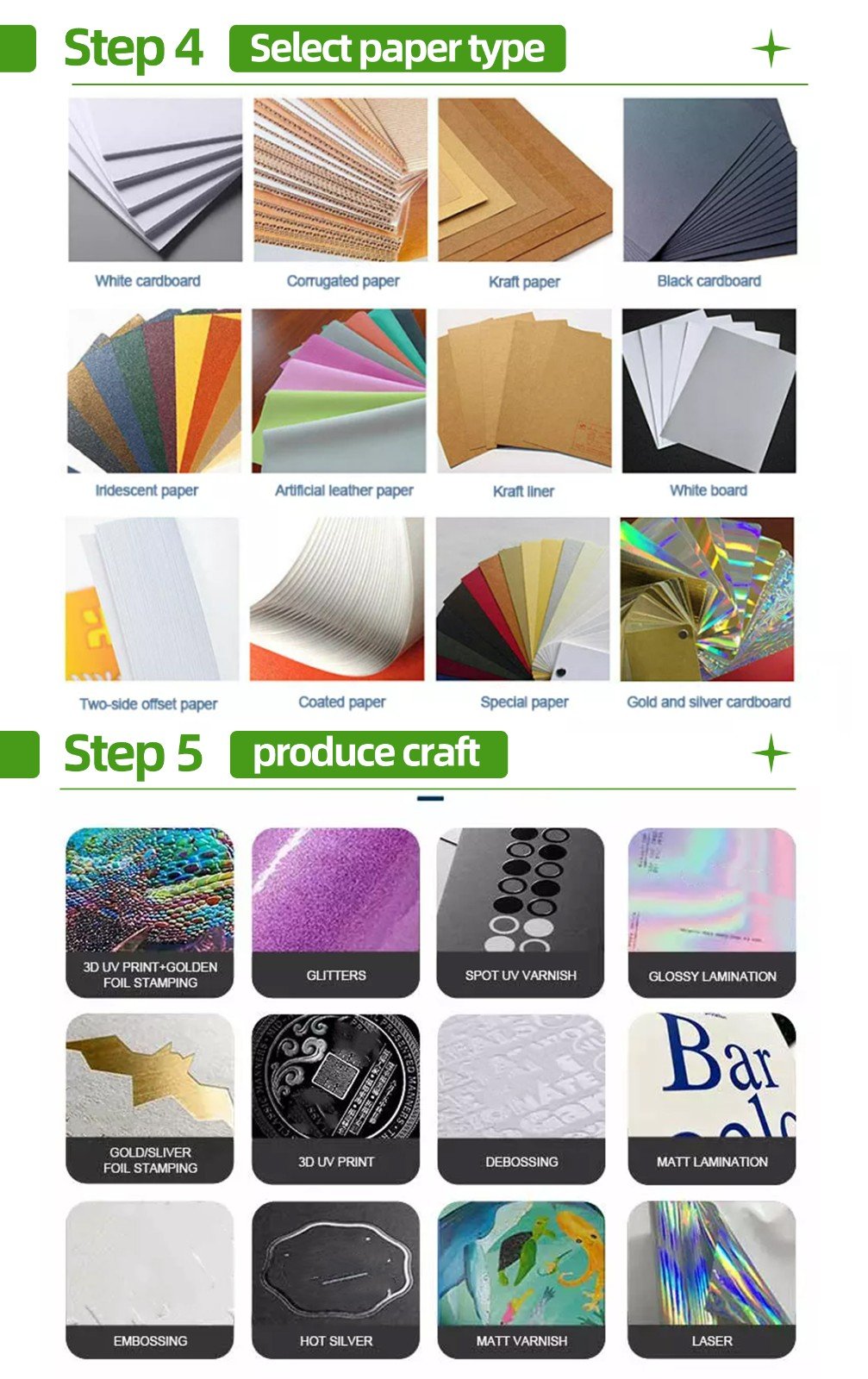

Commonly used packaging box materials include: white cardboard, silver cardboard, gray board, coated paper, corrugated paper, etc.

2. Box type

Front and back buckles (same direction buckles), self-locking bottom, bottom insertion and side bonding, heaven and earth cover boxes, irregular boxes, etc.

3. Printing process

Reverse glazing, embossing, gold stamping, silver stamping, film covering, etc

② Printing, design price, process requirements

Determine the final price based on material, quantity, printing, design, and other requirements.

③ Production cycle

Confirm the design cycle (usually 1-3 days) and delivery cycle (usually 7-15 days).

④ Packaging box design

Provide reference boxes, graphic materials, process requirements, etc. to manufacturers, create documents, and communicate relevant details.

⑤ Packaging box sampling

After the sample is made, the manufacturer confirms that the sample meets their own requirements. If it does not meet the requirements, corresponding modification suggestions are proposed to determine the final plan.

三、 Confirm the order.

After confirming that the sample (packaging box) is correct, place an order to start customized production of the packaging box.