What is a corrugated box?

What is a corrugated box?

1. Corrugated cardboard box is a type of packaging container that uses formed core paper and box board paper to form corrugated cardboard, which is then processed through printing, cutting, nailing, and other processes.

Corrugated cardboard boxes have gradually replaced transportation packaging containers such as wooden boxes with their superior usability and good processing performance, becoming the main force of transportation packaging. In addition to protecting goods, facilitating storage and transportation, it also plays a role in beautifying and promoting goods, and is a green and environmentally friendly product.

2. The composition of corrugated cardboard:

Corrugated cardboard is a multi-layer adhesive body composed of at least one layer of corrugated core paper interlayer (commonly known as "pit paper", "corrugated paper", "corrugated core paper", "corrugated core paper", "corrugated base paper") and one layer of cardboard (also known as "box board paper" or "box board"), which has high mechanical strength, good compressive strength, and shock resistance, and can withstand collisions, impacts, and falls during transportation.

二、 The shape and number of layers of corrugated cardboard boxes

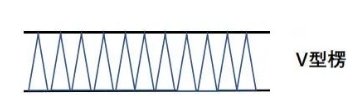

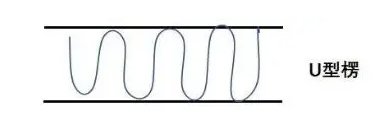

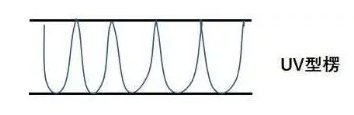

1.According to the cross-sectional shape, it can be divided into V type, U type, and UV type

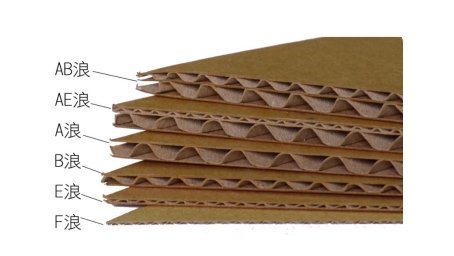

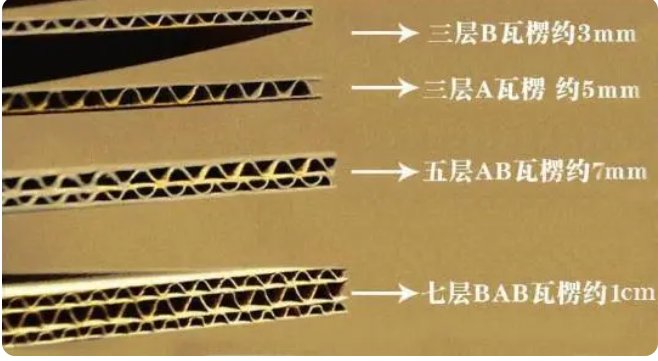

2. According to the size, it can be divided into: A tile, B tile, C tile, D tile, E tile, F tile, G tile, K tile, N tile, O tile, etc.

The commonly used corrugated types are A, B, C, and E tiles:

(1) A-tile: characterized by a small number of corrugations per unit length and a large height of corrugations. A-tile cardboard boxes are suitable for packaging vulnerable items and have a large cushioning force.

(2) B tile: characterized by a large number of corrugations per unit length and a small height of corrugations, it is suitable for packaging heavier and harder items, and is often used for packaging canned beverages and other bottled items. In addition, due to the hardness and non destructibility of B-tile cardboard, it can be used to manufacture complex shaped combination boxes.

(3) C tile: The number and height of corrugations per unit length are between A and B types, and the performance is close to A tile, while the paper thickness is less than A tile. Therefore, it can save storage and transportation costs, and many European and American countries use C tiles.

(4) E tile: Within a length of 30 cm, the number of grooves is generally around 95, and the height of the grooves is about 1.1 mm, which has the characteristics of smaller and harder thickness.

3. The advantages of matching different corrugated cardboard types (e.g. EBA corrugated cardboard boxes):

The outer layer of E-shaped corrugated cardboard has good bi-directional stiffness, reducing the impact of external forces and surface warping. In environments with high relative humidity, the strength loss of the cardboard is minimal;

The middle layer is made of B-type corrugated cardboard, which has sufficient rigidity and resistance to plane pressure to withstand the pressure exerted on the box wall by the packaged goods from the inside;

The inner layer is A-type corrugated cardboard, which has good elasticity and has a cushioning effect when subjected to impact loads. Due to the above advantages, this combination of corrugated cardboard is increasingly widely used in product packaging.

Welcome to contact us for more information!